One step closer to getting the firewall penetrations finished up! I'm now at the point where there is no guidance by Van's regarding locations, so I've been sitting and staring and mulling over what will need to go through the firewall.

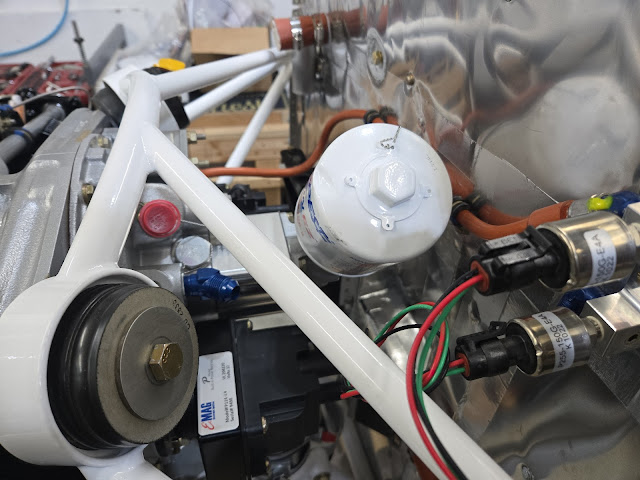

The manifold pressure sensor will connect to cylinder 3, so it'll go through the firewall on the upper right side. Van's provides the kit for plumbing, but not the sensor itself (which I got from AFS along with all of my other engine sensors). I held the brake fluid reservoir up to see where it would go, then just eyeballed where the fitting could go for the manifold pressure plumbing. I put a little fire silicone sealant under the fitting, even thought once the insulation and foil is on, I'll also surround the cutout with sealant.

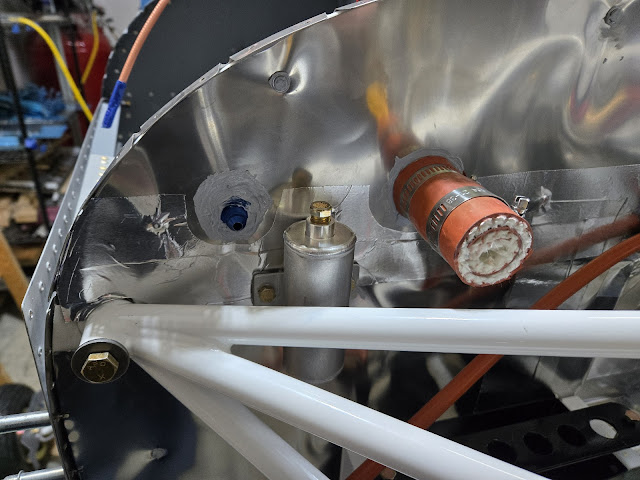

After that was set in stone, I moved on to the right side pass through for wiring. There are a lot of ways to accomplish this, but the most common is to use a flanged tube that extends through the firewall and gets wrapped in fire sleeve. Then, another piece of fire sleeve is inserted into the tube, mostly to aid in sealing around the wires. Once the wires are in place, fire sealant is pumped into the area to provide a gas tight seal. The problem - this little kit of a flange and a small section of fire sleeve is $90! And I need two. I know aviation is expensive, but that seems pretty ludicrous.

Those crazy expensive tubes look awfully similar to a good ol' closet rod hanger. Funny enough, when I searched on that on the forums, I found that a lot of people go the route of the rod hanger. I found two stainless steel hangers on Amazon for $10. Combine that with $20 of fire sleeve and a few hose clamps and I've got pretty much the exact same setup as the real deal for about $130 less.

I drilled a pilot hole in the firewall, then upsized it until my knock out punch would fit. I bought a cheap punch set from Harbor freight. It's made for conduit sizing, so it's a tiny bit off from what I needed for the tube. I used a grinding stone in my die grinder to chew away the last 1/32" I needed to get the tube through. Then I drilled matching bolt holes in the firewall. I made a doubler to go on the forward side of the firewall and riveted it on. I forgot to put sealant under the doubler when I riveted it down, so I slathered it on liberally once I was done. Like with anything else that is permanently fixed to the firewall, it'll get another layer of sealant after the insulation and foil is cut around it.

The manifold pressure sensor AFS sent is nothing special. It looks like it's probably an automotive setup. I decided to mount it vertical instead of horizontal to get the intake tube higher than the level of the firewall fitting. The instructions say to try to keep it so water can't run into the sensor.

Something I just randomly found out while I was digging through various websites and manuals is that the Pmags also use manifold pressure to help with their timing. I will have to put a T in the manifold tubing by the sensor and run it back out the wire penetration to connect to the Pmags (it'll need a second T in the engine compartment since it'll have to split and go to both Pmags).

I repeated the whole process for the left side. Of course it went twice as fast.

There are a couple of other mounts I need to sort out tomorrow - one mount for the AMP shunt and one for an ANL fuse. The ANL fuse was a late addition that I decided on today. Even though aviation alternators have over voltage protection, there's still some paths where a short or other electrical failure can fry downstream systems. The ANL fuse is a 60 amp fuse that will be in between the alternator and everything else. If the alternator truly implodes, I'll have one extra layer of protection. Putting a $20 fuse in to protect many, many thousands of dollars of computers just seems like a no brainer. I guess it's not something most people do (probably simply because it's not included in Dynon's standard engine wiring kit), but it was recommended in Bob Nuckoll's book "The Aeroelectric Connection." That's basically the electrical bible for experimental aviation. Apparently boats also use ANL fuses a lot, so I was able to find the exact fuse and mount sold by aviation suppliers on Amazon (for a fraction of the price of course).

Moving on from the firewall for the day...

The parts I painted yesterday were cured enough to handle, so I went back to working on the wheels. I riveted nutplates onto the nose wheel fairing brackets. These brackets will be what the fairings screw onto. The brackets are attached underneath the axle bolt washer and nut (there are two smaller washers that provide thickness spacers for the brackets), and the front is screwed to the fork using big allen bolts and lock nuts.

The gear leg is drilled through at the top to attach a collar with a bolt. This collar acts as the rotation limiter by bumping up against allen bolts that are screwed into the top of the fork. Simple and effective.

I pumped the fork full of grease and then worked on setting the break out force of the wheel. There are two huge "spring" washers on the bottom of the gear leg, then a nut. I slowly tightened up the nut and moved the wheel back and forth until the breakout force was 22 lbs.