I bit the bullet and set the rivets on the rudder trailing edge. The tape is supposed to hold the skins and wedge together while you rivet, but it really didn't work out that way. I'm not super happy with how they came out, but after licking my wounds and talking to some guys on the VAF forum, I learned that I'm in really good company and most people have very similar experiences on the trailing edges.

The trailing edge on whole is within the spec in terms of being straight, but the skins pillow a bit in between the rivets (and sometimes at the rivet too if the dimples and countersunk wedge don't sit right). Consensus is that this happens all of the time if you just follow the Van's directions. It sounds like significant experience and learning through error are the only ways to correct this. Most people suggested just leaving it, but some have gone the extra step of filling the gaps with fiberglass/epoxy and sanding smooth. I'm setting it all aside for now and will figure out what to do down the road when I work on all of the fiberglass and body work for the plane. As with most aesthetic items so far that bug me, this is yet another one that will only be noticed by someone looking for it specifically.

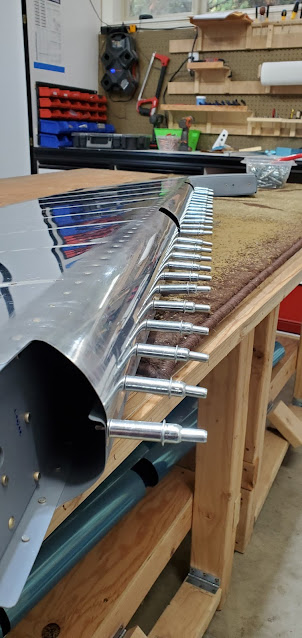

Following the trailing edge, I finished the leading portion of the rudder. In order for the rudder to sit within the recess of the vertical stabilizer, you have to bend the skins and rivet them together to form a curve. I used a 1" broom handle taped to the skin and rolled the skin until it was close to the desired shape.

I made the mistake of assuming that the #40 prepunched holes in the skins were the right size and match drilled them all at that size. Then, as I usually do, I referenced the plans to see which rivets to grab. Oops. Turns out they are 1/8" rivets, which means I had to redrill at #30. Not a big deal, but one of these days I'll have to remember to look 2 steps ahead before finishing a step.

With that, the rudder is pretty much done. The only items remaining are to attach the bearings that marry it with the VS, but I'll wait and do all of that when I put them on the fuselage. I'll also wait and do the fiberglass tips down the road once the plane is largely finished.

Next I'll tackle the elevators. I'm a little nervous about the riveting on the elevator spars just because of the access and the pre-bent skins, but from what I'm learning from all of the other problematic areas I've hit, it's unlikely I'll do any worse than others who have gone before me and still have flyable airplanes. I'm definitely my own worst critic. Even when I know a mistake I've made is really no big deal (like slipping off a rivet and dinging the metal next to them), I shake my head because I know I've made an avoidable mistake. I suppose it's healthy to have that mentality when building a plane, but I need to learn to just smile at goofs and count it as part of the experience.