I worked on the plumbing and access plates today. Everything is done except for sealing the access cover.

Wednesday, June 29, 2022

Tuesday, June 28, 2022

Right Fuel Tank - Leading Edge Rivets

I still had maybe 9 or 10 remaining rivets to do in the very leading edge of the tank. The awkward angle of bucking and using the gun when the tank was in the vertical position meant that I bent over the shop heads more often than not, which is why I got help on the previous tank. I'm impatient though, so instead of waiting for help, I figured I'd give it another shot myself. This time I took the tank out of the jig and tried riveting with it just laying flat on the table. This allowed me to hold the rivet gun much more normally. Reaching around and into the nose with my bucking hand was just on the edge of physical limits, but in the end it actually worked out great. I was able to finish up all of the rivets just fine. I wish I had tried this approach on the last tank! Oh well, next plane I guess. Tomorrow I will seal all of the rivet heads and should be able to get all of the plumbing finished up.

Wednesday, June 22, 2022

Right Fuel Tank - Sealing (4)

I riveted the two ribs I had prosealed yesterday then did the inboard and outboard ribs.

Tuesday, June 21, 2022

Right Fuel Tank - Sealing (3)

Nothing too exciting to show, but I got two more ribs gooped up and clecoed in. For a split second I thought about going ahead and riveting them with the proseal wet, then I came to my senses. I'll wait until tomorrow!

Wednesday, June 15, 2022

Right Fuel Tank - Sealing (2)

This afternoon I riveted the three ribs that I prosealed last night. All in all it went pretty well. I'm done with these ribs except for the couple of rivets along the very nose of the tank. I attempted to do those by myself, but just like on the other tank, the rivets came out pretty bad because of the awkward angle required. I'll get some help doing these.

Tuesday, June 14, 2022

Fuel tanks - Leak Testing & More Sealing

Time to see if all of the work has paid off. After a few false starts due to caps that weren't quite tight enough and were leaking, I got things sorted out and started the leak test on the left tank. All this involves is putting a schrader valve in the drain opening, capping the fuel pickup fitting, and putting a balloon on the vent line. It only takes 1-2 psi to do the check, so just enough to blow up the balloon a little bit is all that is needed.

I went ahead and got started on the ribs of the right tank. It's amazing how much faster things go the second time around. I prosealed and clecoed 3 ribs. I'll shoot the rivets tomorrow night.

Sunday, June 12, 2022

Right Fuel Tank - Sealing Begins

Here we go again! Same story, different tank - scuff, clean, and start with the goop. Having one tank under my belt (although not leak tested yet) definitely made this go faster. I back riveted the stiffeners and fuel tank filler flange and squeezed the rivets on the drain.

Saturday, June 11, 2022

Left Fuel Tank - Done?

I bit the bullet and decided today was the day to fully seal the left tank! I went through the normal motions of ensuring mating surfaces were scuffed and cleaned, then just to make cleanup easier, I taped off the skins just above where the baffle will set. I've seen two methods of sealing the baffle - the Orndorff method that lays down proseal along the entire width of where the baffle flange will go, and the Van's method of only putting a bead down just inside the rivet holes. I get why Van's does it the way they do, but given that the rear baffle is the most common source of leaks, I kind of wanted to err on the side of more surface area than less. Maybe for the next tank I'll do it differently, but for this one I put proseal over the entire surface that the baffle flange will rest against.

Wednesday, June 8, 2022

Left Fuel Tank - Plumbing (2)

I got to wade around in proseal today! That's always a good time. To kick things off, I cut and bent the fuel float sender wire and got it as close to "good" as I could (probably need to play around with it a bit yet though). The float is supposed to lie within 1/8" of the top and bottom skins as it moves back and forth, but because of the curve of the top skin, if I get it within 1/8" on the bottom, then the angle of it as it's in the full position puts part of it at almost 1/2" from the skin (the other end of the float still almost touches). I'm not sure if that's a big deal or not, considering I'd rather it be super accurate towards empty than at full. I'll always use a dipstick anyway, and I'll also be putting a fuel totalizer in, so the float senders aren't the only game in town. I'll look at it with fresh eyes another time. I retested the sender across the entire range from full to empty to make sure the resistance readings were correct.

Then I started with a bunch of proseal. I cleaned and scuffed all of the parts up and started with the fittings on the inboard rib and access plate. I didn't get many pictures of the process, since once the proseal comes out I don't really want to be messing with my phone. With the 90 degree fuel pickup fitting and straight vent fitting in, then I moved to the inside portions and installed the pickup tube itself and hooked the vent line up. Lastly, I installed the fuel sender body in the access plate. It just gets a ring of proseal as a gasket, and the screws just push through the sealant and gush out to create a barrier of proseal as well. The instructions call out that one screw needs to seat metal to metal though, so I kept one clean. I'm not really sure why that is the case, since there's nothing about it that would ground it or complete any kind of circuit. I'll have to reread that section and see if I can figure out why. It's possible that they just meant that the center screw has to stay clean.

One thing that I noticed while looking at my right tank skin is the fact that there are a number of holes that ended up kind of oblong. That was the first tank I drilled and was before I had figured out the secret behind getting the ribs in place. I think a lot of the ribs were under major tension and the clecos probably went in at an angle. Since the rib material is way stiffer than the skins, the rib holes dictated where the drill went. That meant the ribs turned out just fine, but the skin holes sometimes got elongated as the drill angled to find the rib hole. Most of the holes are fine, and for the few that are sprinkled around the tank, I can just use the "oops" rivets to upsize the holes. However, for whatever reason, both end rib locations were worse than anywhere else. It's totally fine to use oops rivets, but not too many in one place. So instead of going overboard on the end ribs, I decided to just up the size of rivets to 4-4 instead of the 3's. I re-drilled all of the end rib holes to 1/8" and re-dimpled to #40. It's probably overkill to do that many, but I figured it would look better to have a whole row of the larger rivet heads vs random ones. Not that it'll be noticeable anyway, but I'd know!

Sunday, June 5, 2022

Left Fuel Tank - Plumbing

Today I got a lot of "education" done, but not much actual work. I got my flaring tool the other day, so figured I'd hammer out the tank plumbing today and be ready to seal the left tank in the next day or two. Instead, I spent a few hours dialing in the flaring tool and a few hours researching torque ranges for fittings (it took hours because no reference seems to agree with the others).

The Rigid flaring tool works great, although I did have to modify how it is supposed to be used because of how soft the aluminum tubing is. The aluminum tubing Van's supplies is 3003 aluminum, which is very soft, at least relative to something like 5052, which is more commonly used in aircraft. For something as ho hum as a fuel vent line that will see no pressure or stress, the 3003 is actually nice though, because it's easily bent and worked through the ribs of the tank. The gotcha is that it's really easy to over flare using the Rigid tool. The tool has a clutch built it that is disengages the pressure at the "correct" amount of flare. I'm sure it works great for stainless steel or copper, but it's too aggressive for the 3003. It took me a lot of playing around to figure out just how many turns of the handle made the perfect flare (4.25). This was a couple of turns before the clutch would have normally released. After a bunch of experimenting, I was able to get pretty consistent flares though. Like anything, prep was key - cut the tubing, square it off with a file or on the sander (the tubing cutter has an angle to the cut), deburr, then lubricate with oil/Boelubeto help the flare die move smoothly.

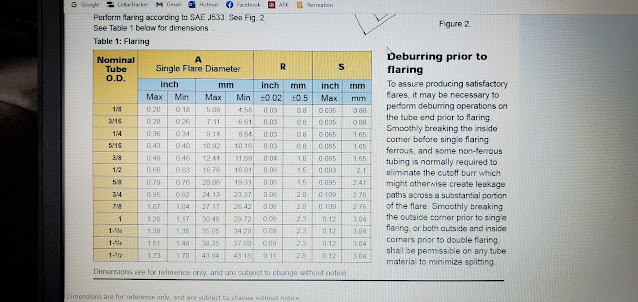

I found someone had posted a nice chart on VAF to show what the flare diameter should be based on tubing size.

Once I had flaring figured out, I flared the end of the roll of aluminum tubing that comes in the kit and then started figuring out how much to cut off for the vent line. In the end I had to insert then pull the tube out 3 or 4 times and cut off more and more until I got it right. The only reason it was a little iffy and not a straight forward measurement was because of the angles that are required in the inboard bay where it attaches to the bulkhead union fitting.