It's been too long since I've been able to work on the plane! Today Rose continued to help me rivet the bottom forward fuselage. Doing this myself would have taken days of awkward positioning and goofy jigs to hold bucking bars, not to mention the sub-par results I would have had. With Rose's help, we got the entire bottom floor done in about 30 minutes! Some aspects of building are much easier to do alone, but when it comes to riveting hard to reach areas, a partner makes things go about 1000x faster. Next up will be the remaining rivets in the forward section, then we'll move to the center and rear fuselage section. That will be when I'll finally be able to flip the canoe over and have a fuselage to sit in and make airplane noises!

Saturday, June 24, 2023

Saturday, June 10, 2023

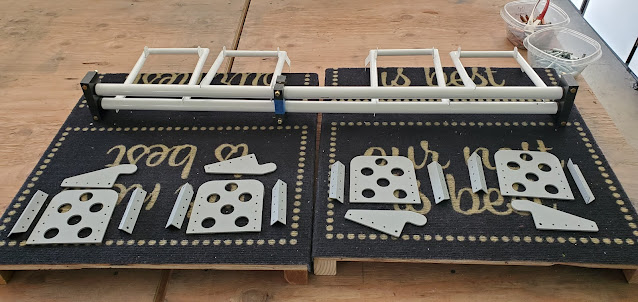

Forward/Center Section Riveting

While I was waiting for my riveting partner to get home, I treated the inside of the rudder tubes. I don't have a ton of primer left, so instead of using primer, I used boiled linseed oil for the tubes. Apparently that is the time tested method for corrosion proofing the inside of the metal in tube/fabric planes. I just poured a bunch in each tube then let it drain out.

Sunday, June 4, 2023

Rudder Pedals & Brakes (2)

Van's calls for using two separate bolts to attach the brake pedal to the rudder bar (not sure what else to call it - it's a pedal, but not really - step on the white bar for the rudder, move up to the actual pedals for brakes). There have been quite a few reports of issues with that setup though. The pedals are slightly tapered from bottom to the top, which means they don't really sit parallel to the welded tabs on the rudder bars. With two separate bolts, the pivot on each side is not in the same plane, so some people have had issues with the brakes binding. There are two solutions that I've found for this - use one long bolt instead of two to keep the pivot point where it needs to be, and add some springs to the brake cylinders to beef up their internal springs for greater power for returning the brakes to neutral.

Bolts that are this long are ridiculously expensive, so instead I decided to go with a 3/16" rod cut to length and threaded/drilled on each end for castle nuts and cotter pins. I started with a piece of stainless rod, but drilling a 5/64" hole in it for cotter pins was easier said than done. Because there really isn't much stress on this part, I decided to switch over to brass instead. It was much easier to work with. The difference between this setup and the two bolts approach was immediately apparent. The single rod decreased the friction of the pedals quite a bit.

Thursday, June 1, 2023

Rudder Pedals & Brakes

It's been a while since I've been able to get into the garage and get much work done. I'm at a bit of a stopping point on riveting the fuselage (waiting for my riveting partner to return from a trip), but I decided to go chip away at some odds and ends. I pulled out the rudder/brake pedals. I've been waffling on whether or not I should prime/paint the pedals. I decided to just do a quick rattle can prime of the angle pieces and back sides of the pedals where things mate together, but left the face of the pedals bare aluminum. I figure anything on the pedals will rub off with use anyway.