I had never fully installed the control sticks and control column to see if my bushing sizes were correct, so I decided to take a step backwards and do that to test fit everything (it'll get tight once the seat ribs are in). It all fit really well. I disassembled it all, bagged the hardware and taped it to the control columns, and stored it for later.

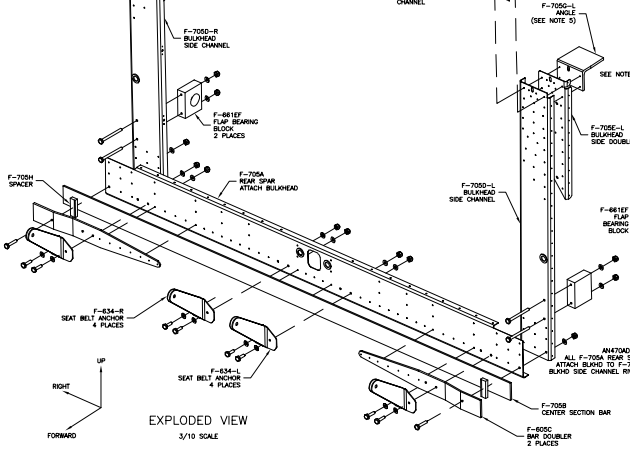

Back to the F-705 bulkhead:

I probably could have just drilled the bar by hand using the holes in the F-705A bulkhead as a guide, but with the thickness of the bar I was worried about not drilling straight, especially once the next layer of the doubler gets drilled. I've learned that rivet holes that aren't perpendicular to the surface end up being an absolute bear to rivet. Of course the same goes for bolt holes. It was awkward, but I used the drill press to drill all of the holes.