I can definitely say that building the fuselage is less tedious than most of the other build I've done up to this point. There are far fewer completed parts to just drill and rivet together, that's for sure. I enjoy the fabrication of parts, so even though it takes time, I'm enjoying the fuselage build so far. The next pieces to create are a couple of large angles that go along the top of the 705 bulkhead.

I still haven't figured out the rationale behind which holes Van's punches and which they leave to the builder, but here again are two missing holes for snap bushings that have to be located and drilled.

The top portion of the bulkhead supports the seat backs. In order to provide some degree of seating flexibility, the top horizontal portion of the bulkhead gets a stack of a few different sizes and shapes of parts that will ultimately provide a catch for a piece of hinged material on the seat back (allowing the seat back to be moved along with the bottom seat cushion to maintain the same vertical angle of the seat back regardless of fore/aft position of the seat bottom). From what I've read, it's of questionable utility, but it's easier to just put it in place now and never use it than put it in place down the road.

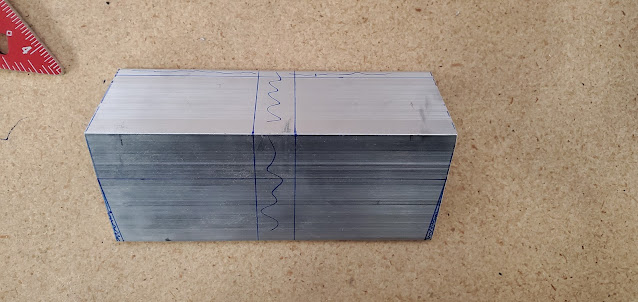

There are three pieces to it all: a shim, a larger piece of aluminum sheet, and a piece of aluminum angle. The sheet gets bent just a slight amount (4 degrees).

The shim that goes underneath the sheet is just a blank, so all of the holes have to be laid out and drilled through both parts.

Maybe this picture will explain better how this all works and goes together. The shim raises the sheet above the bulkhead, and the sheet bend and height of the piece of angle provide the same offset on the rear side. The seat backs will have a piece of aluminum sheet attached to the via a hinge. The seat back can either just rest up against the bulkhead itself, or the hinged sheet can be raised up and captured in one of the two locations created by the stacked parts. That allows the seat back to have a little fore/aft angle movement.

The instructions got very sparse after this. It may as well just say "figure out how to put everything else together." The instructions say to rivet it all together, but they completely forgot to call out some of the other parts of the bulkhead that have to be attached and drilled. You really have to pay attention to the plans themselves to keep from getting bitten! Tomorrow I'll finish up the rest of the pieces the instructions are silent on, then prep for primer.