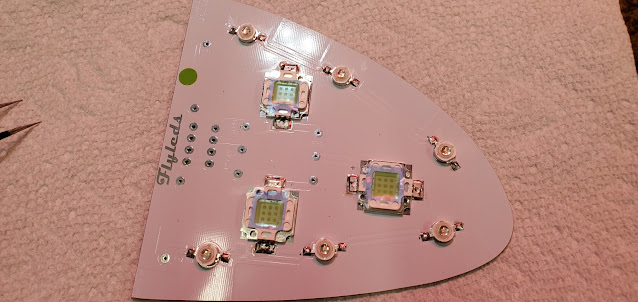

The Flyled wingtip lighting takes a lot more work to put together than the landing lights. The circuit boards are the right general shape for the wing tips, but are far from a match. This isn't the fault of Flyleds - the Van's fiberglass parts are known for being a bit rough. I shaped all of the boards on the sander until they fit.

Sunday, December 31, 2023

Strobes/Position Lights

Saturday, December 30, 2023

Brakes & Landing Lights (2)

Friday, December 29, 2023

Fuel Lines

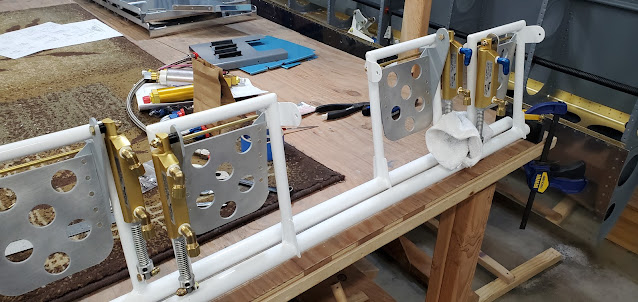

I have the new fuel lines now, so time to start the fight of getting those installed. Since the lines already have the fittings installed, they won't fit through the existing holes in the brackets as they run from the fuel selector valve out to the side skin. As should be expected, opening up the small holes in the four brackets was of course not as easy as just upsizing the hole. The hole for the fuel line is so close to the hole for the brake line that upsizing would make them overlap. The fuel lines came with rubber grommets vs the plastic ones, so perfect holes aren't really necessary. To keep the holes from running into each other, I used a unibit and slowly chewed away at just one side until I had a fairly large hole started and a different center to reference. It's more oval now, but with the grommet is fine. In an ideal world I would have just taken the bracket to the drill press and clamped a sacrificial piece onto the part to put a new center in and used that as my guide, but a couple of these brackets are permanently riveted to the spar carry through.

Wednesday, December 27, 2023

Brakes & Lights

I put castle nuts onto each end of the pivot rod on the brake pedals and secured them with cotter pins (this normally takes one bolt on each side, but I threaded and drilled a brass rod so it's a single piece and won't bind with flexion as easily).

Sunday, December 24, 2023

ADHRS Bracket, Almost 14 Mod & Brakes

I bounced around to a number of different things today. That seems to be the case more often than not now - working on one thing, then moving on to something else while I wait for parts or while I do research on how something is supposed to go together. For the seat back brace, I'm waiting on a part so I can remake one of the side supports. I continued to fit the center portion of the support together, but ran into another problem that I've emailed AntiSplat about (the company who sells the Almost 14 mod). The center cap that goes over the flap housing is supposed to just slide over the top of the Van's housing, line up with the factory holes and then bolt to the seat brace. I'm not sure if I'm doing something wrong or if I have a wonky part. When I line up all of the holes for the flap housing, the cap doesn't even come close to laying against the horizontal brace. So I put a pin in that task and move on to something else while I mull it over.

A long time ago I purchased an ADHRS mount from Van's. I'm going to mount the ADHRS sensor in the tailcone just behind the baggage bulkhead. The sensor has to be mounted so it sets level in level flight. The Van's mount already has the math done to account for the slope of the tailcone, so it was just a matter of sliding the mount in place against the center brace and one of the J stiffeners until a couple of tabs hit. I used my right angle drill and drilled all of the holes (it'll just be pop riveted - there's no need for incredible strength here), then pulled the bracket out and put it in the "to be primed" pile for the spring.

Saturday, December 23, 2023

AntiSplat Almost 14 Mod

I'm still waiting on my fuel lines to be delivered, so I jumped to working on the Antisplat seat back modification. This will be kind of a handful to do because it's not specifically designed for a tip-up canopy, but I think it'll be worth the effort in the end. The biggest headache right out of the gate was due to the fact that I had already drilled holes in all of the original parts, which meant that the new pieces in the modification had to be made to fit the original holes. It's going to be pretty much impossible to explain the modification, but I'll give it a shot.

The original seat back brace comes out and is replaced by an aluminum box that is riveted to the vertical bulkhead pieces and extends back about 4", where the new brace will attach. The biggest problem was trying to get accurate holes drilled in this box, which is sandwiched in between two existing parts that are already drilled. That wouldn't be a big deal if all of the parts were rigid, but there's a lot of wiggle room in the parts still, so it's extremely difficult to put the box in place without impacting the location of the holes in the parts that are on bottom and top of it. It literally took two hours of back and forth clamping and moving and testing to get the left side in a spot where I was confident enough to drill the holes through the top and front of the box.

Sunday, December 17, 2023

Fuel Lines & Almost 14 Mod

Sunday, December 10, 2023

Brakes & Fuel Selector

First up tonight was installing the brake fluid reservoir to the firewall. Because of the variability in firewall forward design, pretty much everything that goes onto the firewall has to be laid out and drilled. Some pass throughs I will probably wait on until I have the engine to be sure I get them in the right location, like the holes for the throttle cable, mixture, etc. The brake cylinder doesn't depend on the engine type, so I went ahead and put it where Van's calls out. It was a little fiddly, since there are two bolt holes to drill, but then a larger 1/2" hole centered below them for the brake line fitting. After a lot of measuring of the part and double and triple checking, I drilled. Thankfully the hole ended up where it needed to be. I still haven't decided if I'll put fiberfrax on the front side of the firewall or not (fiberfrax with stainless foil over it - for greater fire resistance and maybe an extra 60 seconds when I need it most. There are a lot of arguments about whether or not it really matters.). If I do, at some point I'll have to pull this cylinder and all other items mounted to the firewall off so I can make a template to cut out mounting slots in the fiberfrax.

I started measuring and thinking through how the fuel lines would go. The fuel line is still soft aluminum 3003, but it's 3/8" and has a thicker wall thickness than the 1/4" vent tubing. It's much more difficult to bend by hand. I practiced a few flares to ensure I knew what changes had to be made for the bigger material (turns out it's the same 4 1/4 turns by the flaring tool as the smaller 1/4" tubing is), then cut a piece to length and made my first bend....and subsequently put a kink in the pipe because I hit it on the edge of the tubing bender. So scrap that 2' of tubing! That'll be my practice piece I guess. Van's gives you juuuust enough tubing to get by with maybe one oops. I don't like that pressure to potentially put a piece of fuel line in that I'm not 100% happy with, so I decided to order a couple of 12' rolls of extra 3/8 and 1/4 tube. Of course it's backordered until February like everything these days, but it's super cheap, so worth having on the way so I feel confident in the end result.

Saturday, December 9, 2023

Friday, December 8, 2023

Fuel Vent Line - Left & Misc

Work has been pretty all consuming the last few weeks, so I haven't had much time in the garage. I finally had some time to decompress tonight, so got a few things done though.

Just a random tool - I had no idea this existed until I heard someone mention it online. It's a chuck for my right angle pneumatic drill. The drill only takes threaded drill bits, which can make life difficult when you need a very specific size bit. Threaded bits aren't the easiest things to track down (when you just need one and not 50 of one size), so usually have to be special ordered and the shipping costs 10x what the bit does. This chuck is quite small and threads into the drill, but then can accept regular drill bits. Having this earlier in the build would have been a huge help.