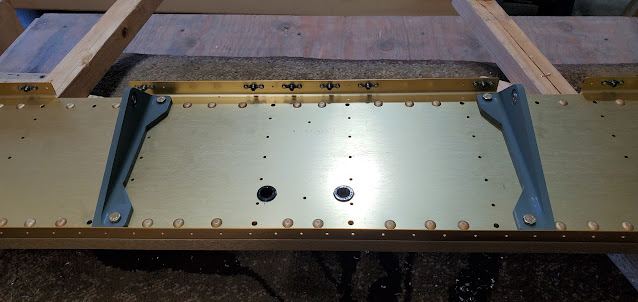

I assembled the 705 seatback bulkhead. It's only been two days since I primed the parts, and given the cooler temperatures, I don't think the primer is fully cured yet. It's hard enough, but it's still definitely not as hard as it is on the skins that I primed a week or so ago. I've found this to be the case with just about every type of primer I've tried so far though - they are good enough to work with after a day or two, but they get tougher and tougher as the weeks go by. The Ekopoxy ended up okay on these parts, but it got beat up just enough while riveting (and dirty because of the light color) that I think it convinced me that I'll have to shoot some paint on the interior after all. I don't think I'll do the entire interior like some people do though. I'll just selectively paint the portions that will be visible after the interior is in, which won't be much. The Ekopoxy will be plenty tough for everything else.

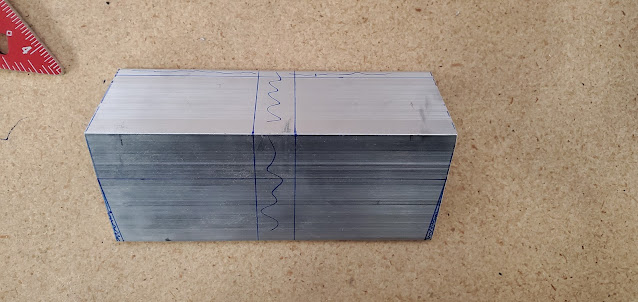

The first portion of the bulkhead assembled was the horizontal seat support.

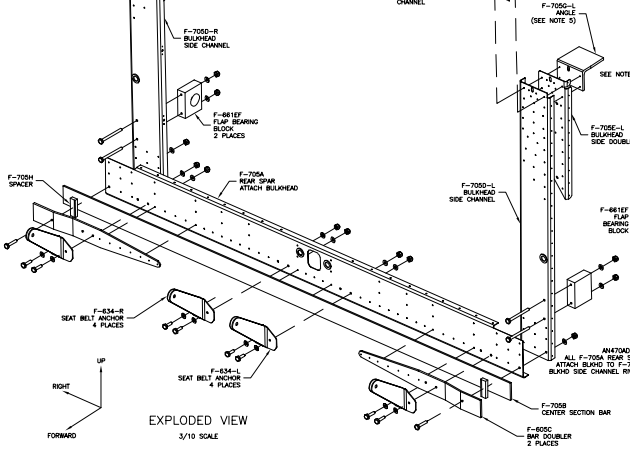

You really have to pay close attention to the plans for this bulkhead. There are a lot of notes and callouts for riveting that could be easy to miss. Some of the holes don't get rivets at all for the tip-up canopy version and others don't get rivets until later in the build process. I taped off holes in the vertical members to keep me from accidentally putting rivets in them. Hopefully I got them all. The big piece of angle (the one with the slot for the canopy latch) also only gets clecoed in at this point. It'll get riveted in after the skins are riveted on. I think it's in that order simply because the skin rivets would be very difficult to get in with the angle already riveted on.

Once the main structure was done, I moved on to the big bar and doublers at the bottom. The last thing to do was to bolt/torque the seat belt anchors on. There is a spacer that gets bolted between the doubler and the bar, but I just bagged the spacer and hardware up and taped it to the bulkhead for now. The instructions say to put it in, but that doesn't make any sense since the bolt also has to go through a seat rib at some point.

I didn't feel like pulling out my spray gun to spray the handful of parts I need to put the 706 bulkhead (behind the baggage compartment) together. I tried a new Rustoleum primer. The spray can primers I've used before have been self etching, but I'm very unimpressed by them. From what I gather, the self etching versions tend to have fewer solids in them, so they don't lay on very well and are pretty fragile for quite a while. I think they probably get much tougher in the weeks/months they are on, but I want something that is at least strong enough to work with after a day or so. So this new primer is just the normal non-etching primer. I thought it was light gray, but turns out it's almost black. I'm going to have quite the spectrum of primer colors in the plane.

I sprayed the parts and snuck a hair dryer out of the house to make it flash off faster. I should probably just grab a cheap heat gun the next time I'm at Harbor Freight. This primer definitely goes on thicker than the self-etch (and is a lot cheaper). That being said, I think I'll just stick with it for very small one-off parts and go through the trouble of pulling out my spray gun and using Ekoprime most of the time. The Rustoleum spray can nozzle doesn't atomize the paint very well, so it goes on super heavy in a very small area, and at the same time has a ton of overspray. Just doing these few parts took up well over a half of a can because of the overspray, which is pretty ridiculous. It was a good reminder though - HVLP guns really are pretty efficient. I dislike having to mix up the Ekopoxy, and the cleanup is harder because it can set up on parts of the gun, but I've become a big fan of the Ekoprime after trying more and more primers. It's just super easy to work with and clean up. Just for kicks, I found a scrap piece that had the Ekoprime on it from probably 6 months ago. It is very tough. I couldn't scratch through it with an awl without really digging in.

Even though the primer will be soft for at least a week in these temperatures, I wanted to move on with the build. I was ready to rivet, but realized I had forgotten to cut half holes out of the edges of one of the doubler pieces to allow a snap bushing (the full hole is in the 706 bulkhead). So I clecoed it onto the bulkhead, traced the holes onto the part and drilled/filed the holes. When I was 3/4 done, I realized I had flipped the part when tracing the holes, and it's not symmetrical. Chalk up another oops. Instead of ordering a new part, I rummaged through some of my scrap sheet metal and found a piece of the same thickness. It didn't take long to remake the part and get it primed. So that's where I'll pick up tomorrow.